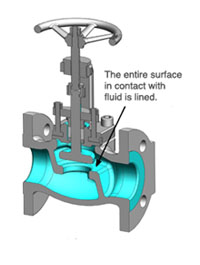

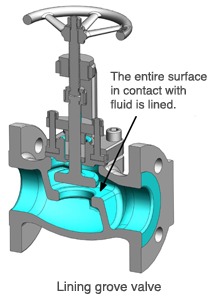

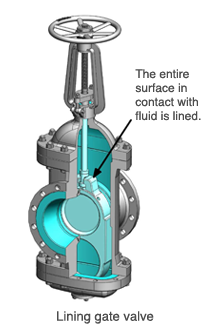

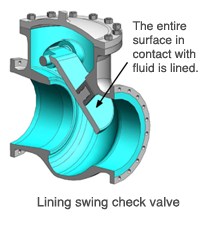

Lining Valve

Valves used in seawater systems are always subject to metal corrosion due to the exposure to seawater, so their life period gets reduced shorter. On top of that, there are maintenance hurdles from sea creatures like barnacles and oysters clinging to the valves and hampering their operation and sealing performance.

Lining Vales, lined with fluorocarbon resin over the entire inner surface are a complete solution for all these issues.

Lining Vales, lined with fluorocarbon resin over the entire inner surface are a complete solution for all these issues.

Although the standard lineup for the lining valve comprises a globe valve, gate valve, and check valve (lift check, swing check), butterfly valves can be made as well. Please contact our sales representative to inquire.

Features

• Entire surface lined with fluorocarbon resin

All valve parts that come into contact with fluid, including the inner wall of the body, disc, and stem, are coated with fluorocarbon resin. Since metal is not exposed to fluid, metal corrosion, which was an inevitable issue with metal valves, will never again be a problem.

• Exceptional corrosion resistance

ETFE, a new breed of fluorocarbon resin, is used for the lining material.

ETFE demonstrates excellent corrosion resistance not only against seawater, but also against most chemicals including strong acids (sulfuric acid, hydrochloric acid, etc.) as well as strong alkalies (sodium hydroxide, etc.).

ETFE demonstrates excellent corrosion resistance not only against seawater, but also against most chemicals including strong acids (sulfuric acid, hydrochloric acid, etc.) as well as strong alkalies (sodium hydroxide, etc.).

• High sealing performance

The seal surface of the valve seat is coated with the fluorocarbon resin ETFE, which provides high elasticity. Small substance that will be buried in the seal surface, thus preventing leakage. Even if the seal surface gets damaged, it can be resolved by lapping the surface.

• Excellent maintenance

ETFE has excellent deposition properties, allowing for easy repairing on the spot.

ETFE also makes surfaces more repellent, thus reducing the amount of shellfish and seaweed clinging to the surfaces compared to valves and piping lined with rubber or polyethylene, materials often used for seawater systems. Moreover, surfaces coated with ETFE will be minimally adhesive, so shellfish, etc. clinging to them can be easily removed.

ETFE also makes surfaces more repellent, thus reducing the amount of shellfish and seaweed clinging to the surfaces compared to valves and piping lined with rubber or polyethylene, materials often used for seawater systems. Moreover, surfaces coated with ETFE will be minimally adhesive, so shellfish, etc. clinging to them can be easily removed.

Specifications

| Name | Lining valve | |

| Body Material | JIS SCPH1, JIS SCPH2, JIS FCD450-10, etc. |

|

| Fluid | Seawater, chemicals such as acid and alkali, food products |

|

| Size | Globe Gate (parallel slide) Swing check Lift check |

20 mm – 250 mm 100 mm – 700 mm 65 mm – 700 mm 20 mm – 50 mm |

| Pressure Class | Class 150, class 300, JIS 10K, 20K, etc. | |

| Connection Form | Flanged | |

| Operation Merhod | Manual (including the type with a manual reduction gear) | |

| Operating Temperature | -80 – 70°C | |