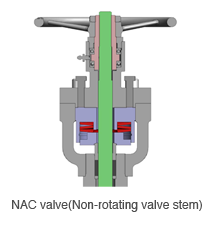

NAC Valve

Designed with a different perspective from the conventional forged globe valve, the NAC valve embodies the concept of “more compact, higher quality, and higher performance.” – “Super Compact, Superior Quality and Superior Performance.” NAC valves could also be produced on a mass production scale and can be delivered quickly.

Features

• Light-weight, compact valve

Compared to the conventional globe valve, this valve is reduced in weight by 3/5 to 1/2 and in height by 3/4 to 2/3.

(As compared with our former products)

(As compared with our former products)

• No maintenance required

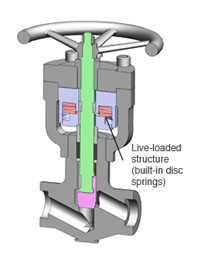

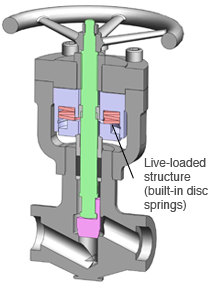

The live-loaded mechanism (built-in disc springs) in the upper gland packing has enabled the packing to sustain its clamping force for an extended period of time, and the need for retorquing has been eliminated as a result. (Set bolts for retorquing are provided in case of leakage.)

• Ease of maintenance

A yoke with a wide opening and a packing that can be removed together with the stem have made it easier to perform maintenance.

The time it takes for disassembly and packing replacement has been reduced by 1/3, and assembly can now be completed in half the time required for previous models.

(When compared with our own products)

The time it takes for disassembly and packing replacement has been reduced by 1/3, and assembly can now be completed in half the time required for previous models.

(When compared with our own products)

Specifications

| Name | NAC valve | |

| Body Material | ASTM A 105M, ASTM A 182M F22 | |

| Operation Method |

Manual(An electric operator is available on request.) Rotating valve stem used for sizes of 25 mm and below, and non-rotating valve stem for 40 mm and 50 mm |

|

| Connection Form |

Socket weld | |